SH Single Cylinder Hydraulic Crusher

Keyword:

Category:

Detail

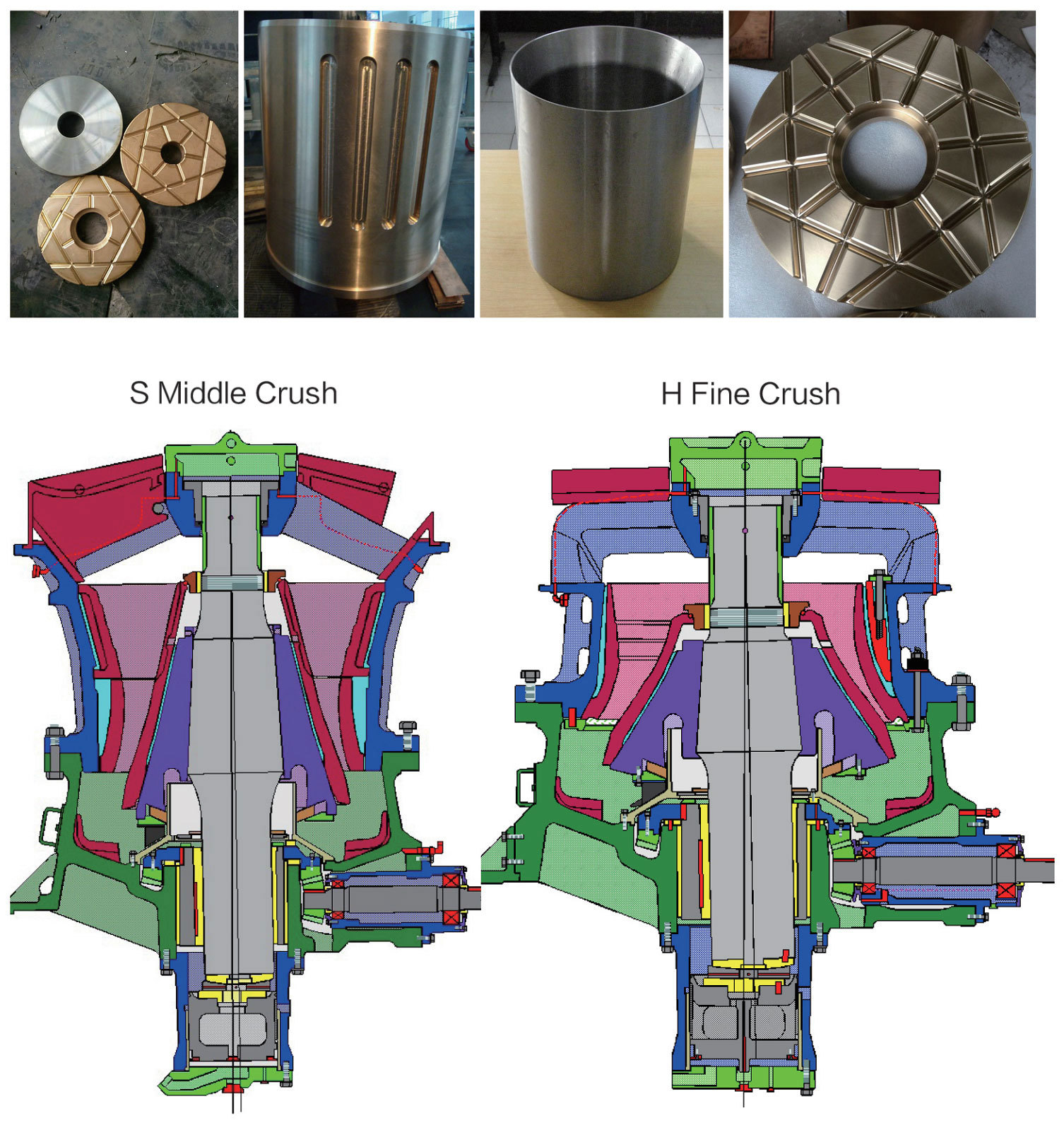

SH single cylinder hydraulic cone crusher is a set of mechanical, hydraulic, electrical, automation and intelligent control technology in one, with greater processing capacity, more safe and intelligent, achievement more efficient cone broken and other product characteristics.

S Middle Crush

| There are three standard crushing cavity types to choose from: MC = medium coarse C = coarse EC = very coarse Standard production capacity at Capacity tight-edge discharge port CSS(mm) (tons/hour) |

|||||||||||||||||||||

| Type S | Power/kw | Max Feed Size/mm | 19 | 22 | 25 | 29 | 32 | 35 | 38 | 41 | 44 | 48 | 51 | 54 | 60 | 64 | 70 | 76 | 83 | ||

| S90 | 90 | Max Feed Size/mm | 240 | 85 | 92-115 | 101-158 | 107-168 | 114-143 | 121 | ||||||||||||

| C | 200 | 70 | 76-95 | 82-128 | 90-112 | 96 | |||||||||||||||

| S160 | 160 | EC | 360 | 126 | 138-173 | 147-230 | 156-293 | 165-310 | 174-327 | 183-344 | 196-306 | 205-256 | 214 | ||||||||

| C | 300 | 108 | 116-145 | 127-199 | 135-254 | 144-270 | 152-285 | 161-301 | 169-264 | 108 | |||||||||||

| MC | 235 | 91 | 98-123 | 106-166 | 116-218 | 124-232 | 131-246 | 139-261 | 147-275 | 154-241 | 165 | ||||||||||

| S250 | 250 | EC | 450 | 267 | 282-353 | 298-446 | 313-563 | 334-601 | 349-524 | 365-456 | |||||||||||

| C | 400 | 225 | 239-299 | 254-381 | 269-484 | 284-511 | 298-448 | 318-398 | 338 | ||||||||||||

| MC | 300 | 195 | 214-67 | 228-342 | 242-435 | 256-461 | 270-486 | 284-426 | 303-378 | 317 | |||||||||||

| S315 | 315 | EC | 560 | 349 | 368-460 | 392-588 | 410-718 | 428-856 | 465-929 | 89-978 | 525-1050 | 562-983 | 604 | ||||||||

| C | 500 | 318 | 336-420 | 353-618 | 376-753 | 394-788 | 411-823 | 446-892 | 469-822 | 504-631 | |||||||||||

H Fime Crush

| Multiple crushing chamber types are available for selection: EEF=ultra-fine, EF=ultra-fine, EFX=quasi ultra-fine, F=fine, MF=medium fine, M=medium, MC=medium coarse, C=coarse, CX=quasi ultra-fine, EC=extra coarse | ||||||||||||||||||||

| Type H | Power/kw | Max Feed Size/mm | Standard production capacity at Capacity tight-edge discharge port CSS(mm) (tons/hour) | |||||||||||||||||

| H90 | 90 | EC | 135 | 4 | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | 57 | 64 | 70 | |

| C | 90 | 46 | 50-85 | 54-92 | 58-99 | 62-105 | 66-112 | 76-128 | ||||||||||||

| M | 65 | 36-44 | 43-53 | 46-89 | 50-96 | 54-103 | 57-110 | 61-118 | 70 | |||||||||||

| MF | 50 | 36 | 38-67 | 38-74 | 41-80 | 45-76 | 48-59 | |||||||||||||

| F | 38 | 27-34 | 29-50 | 31-54 | 40-71 | 44-68 | 47-53 | |||||||||||||

| EF | 29 | 32-57 | 35-48 | 38 | ||||||||||||||||

| H160 | 160 | EC | 185 | 30-40(80% fineness less than 4.5-5.5mm) | ||||||||||||||||

| C | 145 | 69-108 | 75-150 | 80-161 | 86-171 | 91-182 | 104-208 | 115-208 | ||||||||||||

| MC | 115 | 57 | 66-131 | 71-142 | 76-152 | 81-162 | 86-173 | 98-197 | 109-150 | |||||||||||

| M | 90 | 64-84 | 62-140 | 67-151 | 72-162 | 77-173 | 82-184 | 93-145 | ||||||||||||

| MF | 75 | 61 | 65-106 | 69-131 | 75-142 | 80-152 | 86-162 | 91-154 | 104 | |||||||||||

| F | 50 | 48-78 | 51-83 | 54-88 | 70-115 | 76-124 | 81-126 | 87-114 | 92 | |||||||||||

| EF | 35 | 59-96 | 63-103 | 68-105 | 72-95 | 77 | ||||||||||||||

| H250 | 250 | EC | 215 | 70-90(80% fineness less than 5-5.6mm) | ||||||||||||||||

| C | 175 | 101 | 114-200 | 122-276 | 131-294 | 139-313 | 159-357 | 175-395 | 192-384 | |||||||||||

| MC | 140 | 97-122 | 109-218 | 117-292 | 125-312 | 133-332 | 151-378 | 167-335 | 183-229 | |||||||||||

| M | 110 | 117-187 | 105-262 | 113-282 | 120-301 | 128-320 | 146-328 | 161-242 | ||||||||||||

| MF | 85 | 114 | 124-227 | 126-278 | 136-298 | 145-318 | 154-339 | 176-281 | 194 | |||||||||||

| F | 70 | 90-135 | 96-176 | 104-191 | 134-245 | 144-263 | 153-281 | 163-299 | 186-248 | |||||||||||

| EF | 38 | 112-206 | 120-221 | 129-236 | 137-251 | 156-208 | ||||||||||||||

| H315 | 315 | EC | 275 | 100-125(80% fineness less than 6-7.5mm) | ||||||||||||||||

| CX | 245 | 177 | 190-338 | 203-436 | 216-464 | 246-547 | 272-605 | 298-662 | 382-511 | |||||||||||

| C | 215 | 174-194 | 187-374 | 200-488 | 212-519 | 242-592 | 268-654 | 293-521 | 323-359 | |||||||||||

| MC | 175 | 171-190 | 184-367 | 196-480 | 209-510 | 238-582 | 263-643 | 288-512 | 317-353 | |||||||||||

| M | 135 | 162-253 | 174-426 | 186-455 | 198-484 | 226-552 | 249-499 | 732-364 | ||||||||||||

| MF | 115 | 192 | 197-295 | 211-440 | 226-470 | 240-500 | 274-502 | 302-403 | ||||||||||||

| F | 85 | 195-304 | 207-369 | 222-396 | 237-423 | 252-450 | 287-451 | 318-363 | ||||||||||||

| EF | 65 | 211-293 | 210-328 | 225-352 | 241-376 | 256-400 | 292-401 | 323 | ||||||||||||

| H500 | 500 | EC | 300 | 227-316 | 244-298 | 261-290 | ||||||||||||||

| C | 240 | 406 | 448-588 | 477-849 | 544-968 | 601-1070 | 658-1172 | 725-1291 | 782-1393 | 849-1512 | 906-1331 | |||||||||

| MC | 195 | 380-440 | 433-636 | 461-893 | 525-1018 | 581-1125 | 636-1232 | 700-1357 | 756-1464 | 820-1461 | 876-1286 | |||||||||

| M | 155 | 400-563 | 406-723 | 432-837 | 492-954 | 544-1055 | 596-1155 | 657-1272 | 708-1373 | 769-1370 | 821-1206 | |||||||||

| MF | 100 | 379-424 | 407-716 | 428-786 | 455-836 | 519-953 | 573-1054 | 628-1154 | 692-1271 | 746-1372 | 810-1248 | 865-1098 | ||||||||

| F | 90 | 357-395 | 385-656 | 414-704 | 434-765 | 462-814 | 527-928 | 592-942 | 638-789 | 702 | ||||||||||

| EF | 80 | 280-405 | 304-517 | 328-558 | 352-598 | 442-752 | 470-800 | 535-912 | 592-857 | 649-718 | ||||||||||

| H600 | 600 | EC | 370 | 376-639 | 400-680 | 455-775 | 503-728 | 551-669 | ||||||||||||

| C | 330 | 480-640 | 547-1277 | 605-1411 | 662-1546 | 730-1702 | 787-1837 | 854-1994 | 912-2128 | |||||||||||

| MC | 260 | 541 | 540-772 | 616-1232 | 681-1362 | 746-1492 | 821-1643 | 886-1773 | 962-1924 | 1027-1613 | ||||||||||

| M | 195 | 552-613 | 576-864 | 657-1231 | 726-1361 | 795-1490 | 876-1642 | 945-1771 | 1025-1538 | 1094-1231 | ||||||||||

| MF | 130 | 514 | 549-933 | 587-1043 | 669-1189 | 739-1314 | 810-1440 | 892-1586 | 962-1604 | 1045-1393 | 1115 | |||||||||

| F | 120 | 531 | 570-832 | 609-888 | 584-993 | 666-1132 | 736-1251 | 806-1370 | 888-1420 | 958-1245 | ||||||||||

| EFX | 100 | 401-502 | 433-631 | 465-678 | 496-724 | 648-945 | 739-985 | 816-885 | ||||||||||||

| EF | 85 | 364-420 | 395-532 | 426-574 | 458-616 | 489-658 | 528-770 | 602-803 | 665-721 | |||||||||||

| EEF | 75 | 309-356 | 328-441 | 356-479 | 384-517 | 412-554 | 440-592 | 520-700 | 593-798 | 665-882 | 718-883 | 790 | ||||||||

| 468-630 | 534-575 | |||||||||||||||||||

Production capacity, ton/hour

(1) The data given is only an approximate indicator of crusher production performance.

(2) The data in the table are aimed at the crusher performance during open-circuit production of dry materials with a pile specific gravity of 1600 kg/m, and assume that the maximum particle size of the feed is the maximum feed particle size allowed by the crusher, and does not contain fine materials smaller than the maximum feed particle size of the crusher and smaller than the tight side discharge port (CSS) of the crusher.

(3) As the selected eccentricity, crushing ratio, crushing function index (Wi) of the material, feed particle size composition, cycle load, water content in the feed, etc. will affect the capacity of the crusher, so, for the specific application, please consult us further.

Related products

Product inquiry